CNC stands for ‘Computer Numerical Control’. That means computer has the ability to change the design patterns into numbers, produced by Computer Aided Design Software (CAD). These converted numbers control the movement of the cutter. In this way, computer controls the cutting and engraving of the objects.

http://www.apa21.org/2013/04/factors-to-consider-when-looking-for-a-cnc-machine-for-sale/

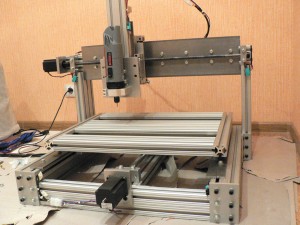

A CNC Laser Cutter allows for extremely precise cutting and engraving of many materials such as wood, foam, concrete, different metals and many others. It contains a sharp and pointed router to produce clean and exact cutting of the material. This sharp cutter can even cut most organic materials and depending on the power metals as well.

This process of cutting is controlled by the computer system in which the required software and hardware are installed. In big industries, a high powered laser cutter is often used to cut sheet and piping materials. Different companies use this technique to increase their outcome. Because less men power is required for this technique and it consumes less time to laser the material in efficient way than the older process to cut the objects. You can attach this machine with your desktop to make designs and images.

High laser beam is required to obtain a clear and clean material. But the amount of laser cutting power is depending on the thickness of the material. It is the most easy and efficient way to laser or cut the materials.

The use of modern Technology has increased in last few decades. These technologies have made everything easy. CNC Laser Cutter allows you to make different patterns and designs on different materials. Some parts of jeweler are also designed and cut by using this technique. There are several methods that are used in cutting using lasers and such methods may include vaporization, melt and blow, melt blow and burn, thermal stress cracking, scribing, cold cutting and burning stabilized laser cutting.

This machine is easy in use and to handle. But a lot of concentration is required to control this machine. It is a safe mode of working especially in industries.

In CNC laser cutter mirrors and lenses are also installed and aligned. After which you can also design create different colors across all types of materials. Pulsed lasers is also a great factor that is very effective in Laser cutting processes specially piercing, or when very small amount of cutting speed is required. The technology of laser cutter is more precise and consumes less energy for cutting metal sheets than plasma cutting. But the maintenance of the machine is very necessary. It should handle with great care. By using CNC laser cutter we are able to design different wooden frames and there are unlimited opportunities for us to deal with this new technology in a useful manner. It increases the productivity of any company. In less time, it gives more outcomes with a small amount of men power. CNC Laser Cutter is very affordable and useful as well. This machine has a high processing speed. You can cut and engrave the material with the same machine. It has made human life easy. The worker has no direct contact with the machine tools; the machine can be controlled through operating system and by pushing just a single button.